Correct Selection of the FLUCAST® Seat and Its Impact on Operational Efficiency

Correct Selection of the FLUCAST® Seat and Its Impact on Operational Efficiency

How targeted material selection of an industrial butterfly valve seat reduces operating costs, minimizes downtime, and extends service life

1. Introduction

In modern industrial operations, there is increasing pressure on equipment reliability, the minimization of unplanned downtime, and the reduction of operating costs. Valves are often perceived as robust devices with a long service life; however, their actual operational durability is largely determined by a single component – the seat.

The seat forms the direct interface between the valve and the conveyed medium. As such, it is exposed to abrasive, chemical, thermal, and mechanical stresses. An incorrect material selection quickly manifests itself in increased wear, loss of tightness, or the need for premature replacement.

2. Why a Universal Seat Does Not Exist

The properties of the seat have a decisive influence on the actual service life of the entire valve.

In industrial practice, the approach of “one material for all applications” is still encountered. However, this concept does not reflect real operating conditions and often leads to:

Different media affect elastomer materials in different ways. Fundamental differences arise especially between:

The correct seat selection must always be based on real operating conditions, not solely on catalogue data.

3. Economic Impact of Proper Seat Selection

Targeted seat selection has a direct and measurable impact on the operating economics of the equipment.

3.1 Valve Service Life

A seat designed for a specific type of abrasion and medium demonstrates:

3.2 Operating Costs

Longer seat service life means:

3.3 Time and Equipment Availability

Every shutdown results in losses of:

Proper seat selection contributes to stable operation without unplanned interventions. A key role is played by ABO valve specialists, who already evaluate operating characteristics, medium type, and operating regime during the application design phase. This makes it possible to select a solution that minimizes maintenance interventions, shortens downtime, and increases long-term equipment availability.

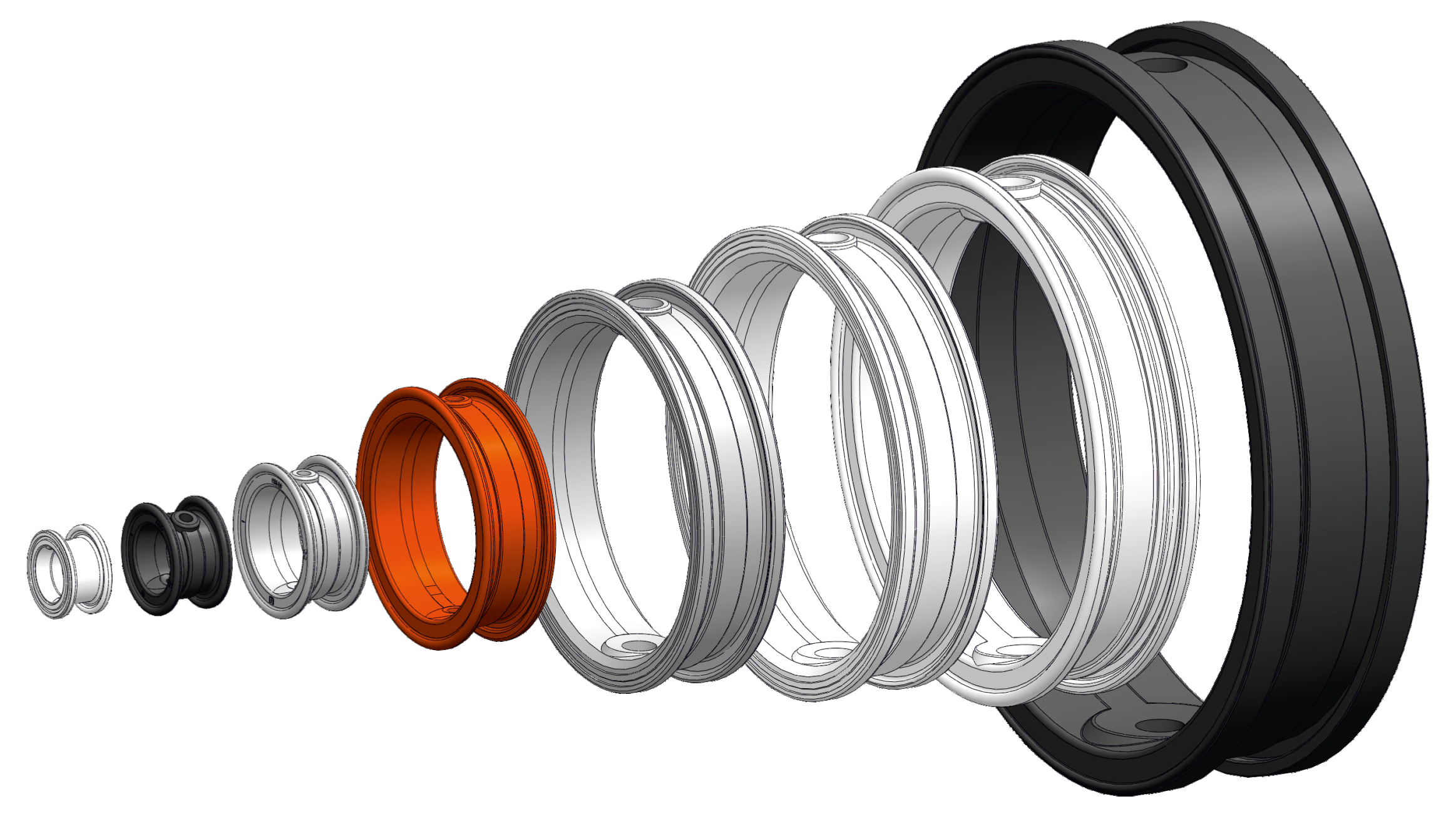

4. FLUCAST® Range – A Targeted Approach to Materials

FLUCAST® seats were developed as a range of specialized materials, where each type addresses a different type of operational load.

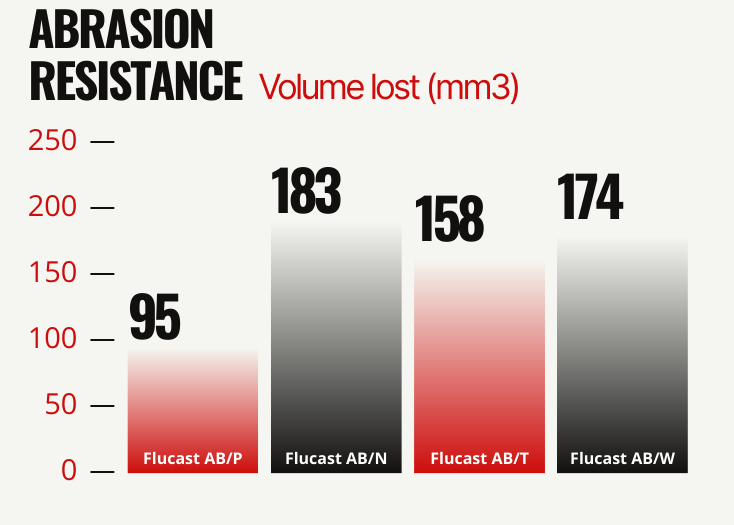

4.1 FLUCAST® AB/P – Dry Abrasion

Designed for applications with bulk and powder media. High elasticity and optimized hardness reduce wear under dry abrasive conditions.

Typical benefits:

4.2 FLUCAST® AB/N – Oil Abrasion

An NBR compound designed for contact with mineral and vegetable oils. Prevents material degradation in oil-based applications.

Typical benefits:

4.3 FLUCAST® AB/T – Chemical Load and Higher Temperatures

An EPDM compound with high resistance to chemicals and temperatures up to 130 °C. Certified for food industry applications.

Typical benefits:

4.4 FLUCAST® AB/W (White) – Food Industry

A white seat designed for dry abrasive applications in the food and pharmaceutical industries.

Typical benefits:

5. ABO valve as a Technical Partner

At ABO valve, we do not perceive the seat as a catalogue item, but as a strategic element influencing operational reliability and total cost of ownership of the valve.

Our technicians and sales engineers:

The result is a solution that makes technical and economic sense in the long term.

5.1 Reference Operating Case – Gas Industry

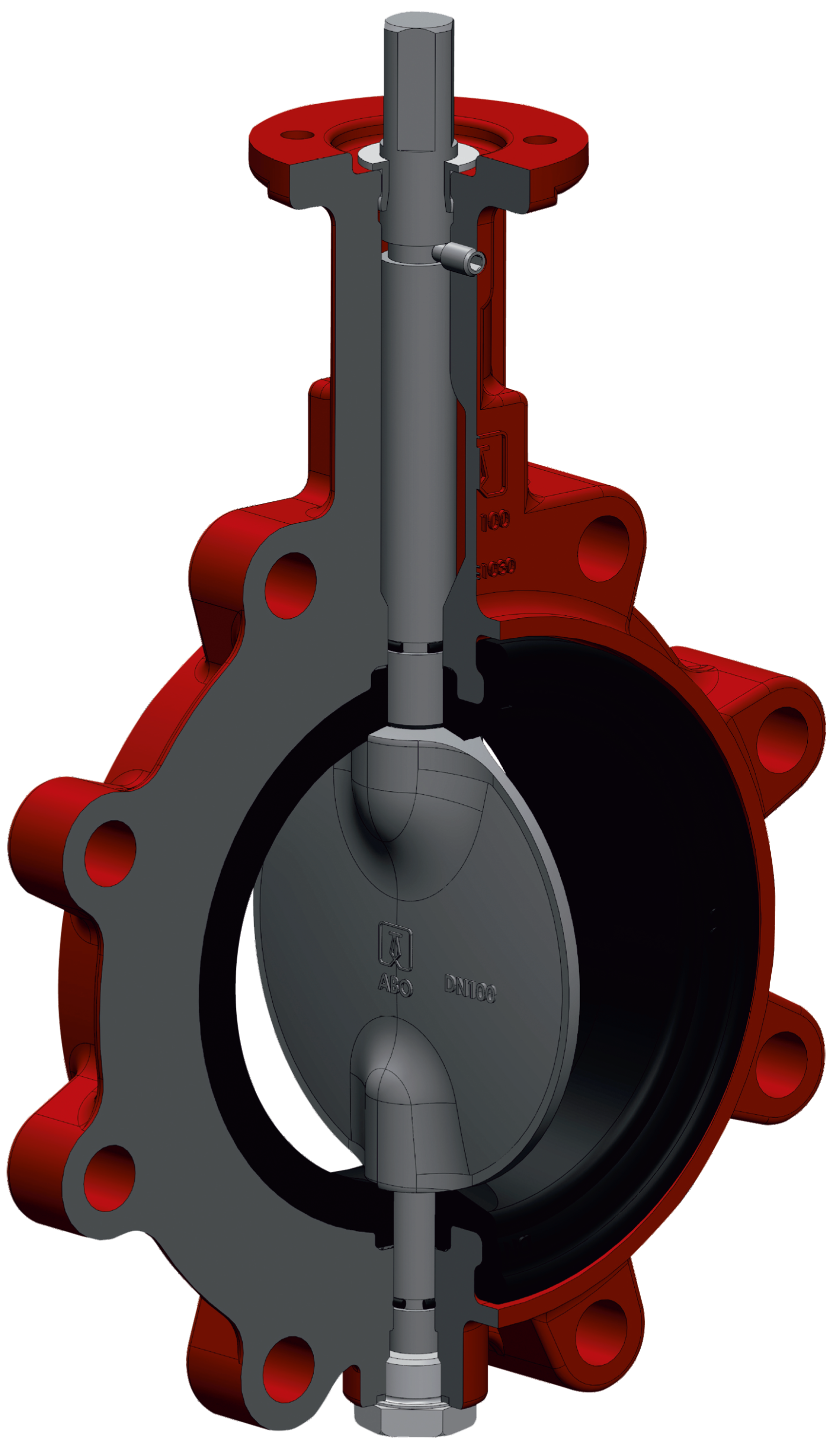

As part of a new technological installation, Series 900 butterfly valves with an inflatable FLUCAST® AB/T seat were manufactured and supplied for long-term operation under abrasive conditions.

The valves are installed between two storage tanks in a limestone dosing system. The application is characterized by continuous contact with an abrasive medium and increased demands on sealing performance and long-term stability of material properties.

The selection of the FLUCAST® AB/T seat was based on a detailed analysis of operating conditions, particularly the type of medium and the nature of abrasion. The solution was chosen to extend service intervals and minimize the risk of unplanned downtime during the first years of operation.

6. Conclusion

The correct seat selection is not a detail – it is a decision that:

FLUCAST® seats, combined with the technical expertise of ABO valve, represent a path toward long-term stable, safe, and economically efficient operation.